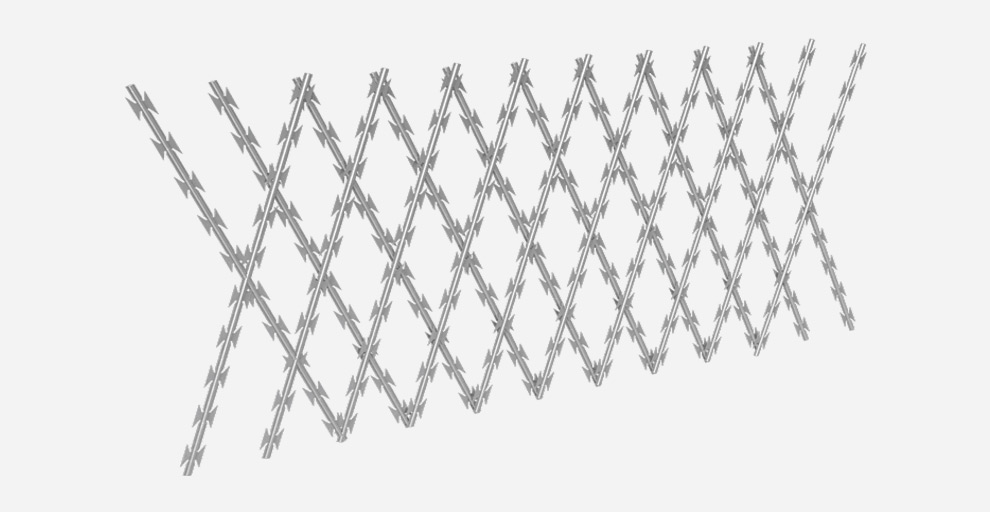

Welded razor wire, also known as welded blade netting, is a high-security fencing solution that consists of straight razor blades welded together in a diamond pattern. This unique design provides both an attractive appearance and practical functionality, making it suitable for a wide range of high-security applications.

Non-climbable and featuring a sharp blade profile, welded razor wire offers a robust structure with a high-strength steel core wire that is exceptionally difficult to cut. This combination of features makes it an ideal choice for high-security applications where deterring climbing and preventing unauthorized access are paramount.

Welded Razor Wire | |||

Model | BTO-10 | BTO-22 | BTO-30 |

Pattern |

|

|

|

Thickness | 0.5mm+/-0.05mm | 0.5mm+/-0.05mm | 0.5mm+/-0.05mm |

Core Wire Diameter | 2.5mm+/-0.1mm | 2.5mm+/-0.1mm | 2.5mm+/-0.1mm |

Blade Length | 10mm+/-1mm | 22mm+/-1mm | 30mm+/-1mm |

Blade Width | 13mm+/-1mm | 15mm+/-1mm | 18mm+/-1mm |

Blade Space | 26mm+/-1mm | 34mm+/-1mm | 45mm+/-1mm |

Hole Pattern | Aperture*Size | Height*Length |

| 75mmx150mm 100mmx200mm 150mmx300mm | 1.2m*6m 1.8m*6m 2.1m*6m 2.4m*6m |

| 75mmx150mm 100mmx200mm 150mmx300mm | |

| 100mmx100mm 150mmx150mm 200mmx200mm |

Welded razor wire mesh is commonly used as protective fence for factories, gardens, prisons and properties, banks, etc.

Welded razor wire is reinforced with a high tensile steel core, providing maximum strength and durability. This reinforcement enhances the overall resilience of the razor wire, making it highly resistant to cutting, bending, and tampering.

Welded razor wire is commonly coated with zinc to improve its resistance against corrosion. The zinc coating serves as an additional layer of protection, making the razor wire highly durable and suitable for a wide range of outdoor and high-moisture environments.