Welded mesh panels can indeed be manufactured using various wire materials such as galvanized wire, stainless steel wire, or non-galvanized wire. The choice of wire material depends on the specific requirements of the application and the desired properties of the panel.

Welded mesh panels are available in a wide range of sizes, apertures (the size of the openings in the grid pattern), and thicknesses. This variety allows for customization based on the specific needs of the project, ensuring that the panel meets the required strength, security, and visibility requirements.

Overall, welded mesh panels offer a versatile and reliable fencing solution for various applications, including gardens, allotments, and construction sites.

Excellent corrosion and rust resistance performance.

Welded mesh panels made from galvanized wire or stainless steel wire exhibit excellent corrosion and rust resistance. Galvanized panels are coated with a layer of zinc, which acts as a protective barrier against corrosive elements such as moisture, chemicals, and environmental factors. Stainless steel panels, on the other hand, possess inherent corrosion resistance due to the properties of the stainless steel alloy used. This corrosion resistance allows the weldmesh panels and other panels to withstand exposure to outdoor elements and harsh environments without succumbing to rust or deterioration.

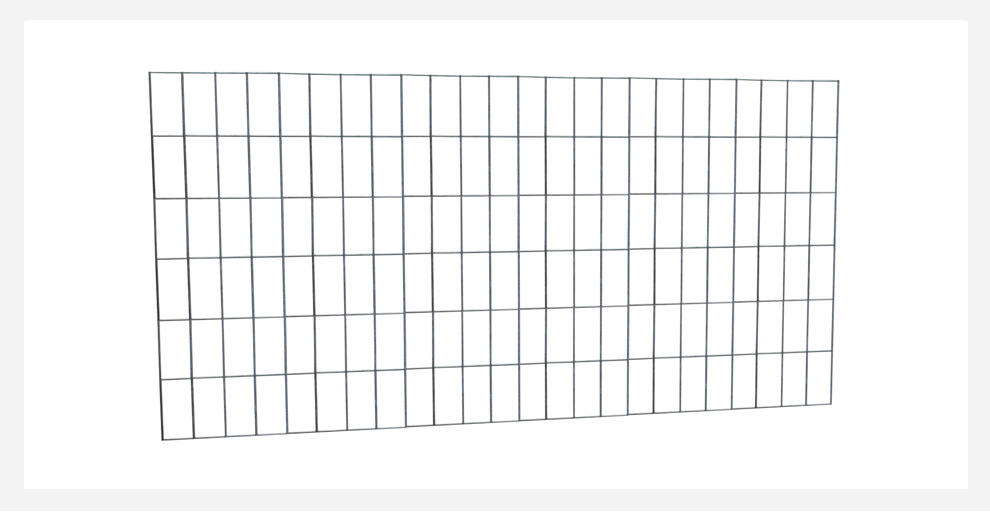

| Welded Mesh Panel | ||

| Hole Size | Wire Diameter mm | |

| In Inch | In Millimeter | |

| 2x2 | 50x50 | 1.6, 2, 2.5 |

| 2x3 | 50x75 | 1.6, 2, 2.5 |

| 3x3 | 75x75 | 1.6, 1.8, 2, 2.5, 3 |

| 2x4 | 50x100 | 2, 3, 4, 5, 6 |

| 4x4 | 100x100 | 3, 4, 5, 6 |

| 2x8 | 50x200 | 3, 4, 5, 6 |

| 1. Standard height: 0.5-2.5m 2. Standard width: 0.5-3.0m 3. Customized size also can be acceptable | ||

Wide ranges of applications: The panel is mostly used in agriculture, construction and security protection. It contains security fencing, pet cages and animal enclosures, Aviaries and bird cages, pond covers and leaf protection, garden fencing, metal fencing, chicken coops, dog fencing, security cages, pet hutches, climbing plant support, etc.

Welded mesh panels are manufactured through a welding process that joins the intersecting wires at their junctions. This process results in a flat and uniform surface, where the wires are securely bonded together. The flat surface ensures that the panel maintains a consistent shape and appearance, contributing to its overall stability and structural integrity.

The welding process used to create welded mesh panels ensures that the wires are fused together, creating a smooth surface without any protrusions or sharp edges. The smooth surface not only enhances the aesthetics of the panel but also minimizes the risk of injury or damage. It provides a safer and more user-friendly solution, especially in applications where people or animals may come into contact with the panel.

The flat and smooth surface of welded mesh panels plays a significant role in their structural stability. The absence of irregularities or deformations ensures that the panel can distribute forces evenly, enhancing its load-bearing capacity. This structural stability is important, particularly in applications where the panel needs to withstand pressure, impacts, or other external stresses.

The flat and smooth surface of welded mesh panels simplifies the installation process. The panels can be easily aligned and secured in place, ensuring a uniform and professional appearance. The flat surface allows for straightforward attachment to supporting structures or frameworks, reducing installation time and effort.